WHAT MAKES LINEN SPECIAL

By Camilla Swart

Did you know that linen fabric is the oldest fibre known to humans?

We have been using linen since 8 000 BCE, and flax fibres more than 34 000 years old have been discovered in a cave in the Republic of Georgia. The ancient Egyptians refined the manufacture of linen fabric immensely. White linen symbolised purity and was worn by priests and royalty.

Today the best quality linen is grown in Western Europe – Belgium, France, the Netherlands, and Poland. Linen Drawer buys linen fabric made from certifiable European grown flax.

Growing flax (linen) has minimal environmental impact. Flax is fast growing and entirely renewable resource. Cultivation does not require lots of irrigation and is mostly fed by natural rainfall. Flax is grown mostly in cool, humid climates with moist soil.

Back to our question – what makes linen special?

- Fast growing, renewable resource, requiring few pesticides and little irrigation

- All parts of the plant are used – bast, seeds, fibres

- Very high fibre strength – durable products

- Hypo-allergenic, naturally anti-bacterial

- Cooling in hot temperatures, warm in cold temperatures

- Multiple end use – clothing, bedding, upholstery, tabling

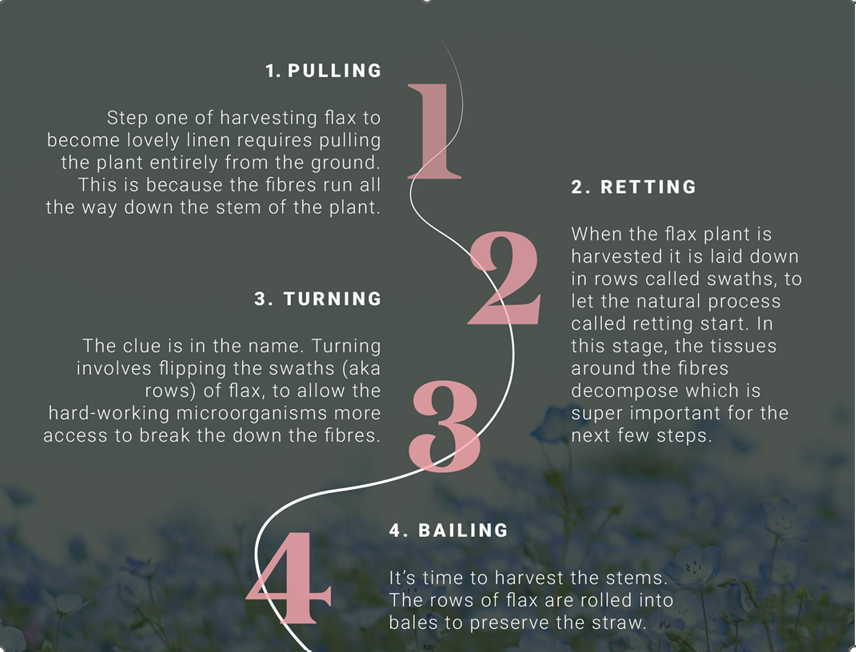

How does this woody plant become a wonderful fabric?

There are several stages to manufacturing linen that are time honoured and traditional. The implements might have modernised but the process is still the same:

- Pulling – the entire plant is pulled from the ground using machines called flax pullers.

- Retting – the pulled plants are laid in tidy rows and nature now works to break down the tissues around the fibres.

- Turning – this is quite literally flipping the pulled swaths over so that their contact with the ground is maximised and the soil micro-organisms can do their work.

- Baling – the swaths are gathered and rolled into bales, which can be stored until they are required.

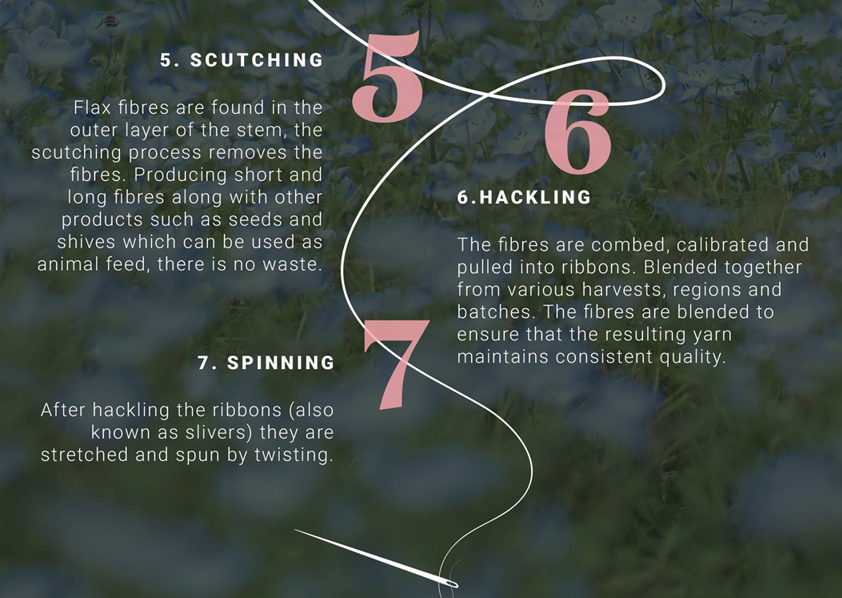

- Scutching – this the first process of turning plants into linen fibres. A mechanical process breaks down the woody bits of the plant – yielding short and long fibres.

- Hackling – the fibres are combed and calibrated and turned into ribbons. Different fibres from differing harvests are blended yielding high-quality yarns.

- Spinning – the final process whereby the fibres are stretched out and twisted together – they can either be spun wet or dry. Wet spinning yields smooth fine yarn suitable for clothing or home textiles. Dry spinning yields coarser yarn ideal for heavier furnishing fabrics.

It is amazing to think that the above process has been used for hundreds of years to produce crisp linen fabric suitable for the most luxurious products! No wonder heirloom bedding and tabling were made from pure linen.

SOURCES:

https://www.youtube.com/watch?v=-ZrZZefkohE

https://www.youtube.com/watch?v=cLOPCAJKeLE

.png)

.png)